Understanding 2WD vs. 4WD Lift Kits

If you’ve ever looked into lifting your truck, you may have noticed that 2WD lift kits often look very different from 4WD lift kits—especially when it comes to subframes. So why do 4WD lift kits typically require a subframe, while 2WD kits do not? Although both types are designed to improve ground clearance and off-road capability, they follow different engineering principles based on how each drivetrain is built.

How 2WD Lift Kits Work

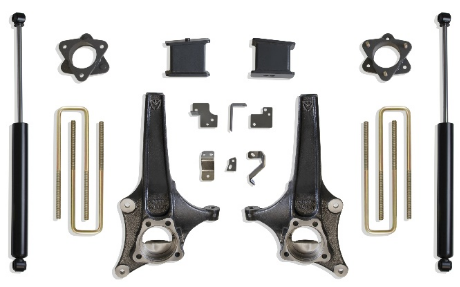

2WD (two-wheel drive) lift kits work within the factory suspension’s normal range of motion. Instead of completely reconfiguring the suspension layout, they use components like lift coils, coil spacers, strut spacers, or coilovers to extend the suspension downward. This creates additional ride height by using part of the suspension’s natural down-travel.

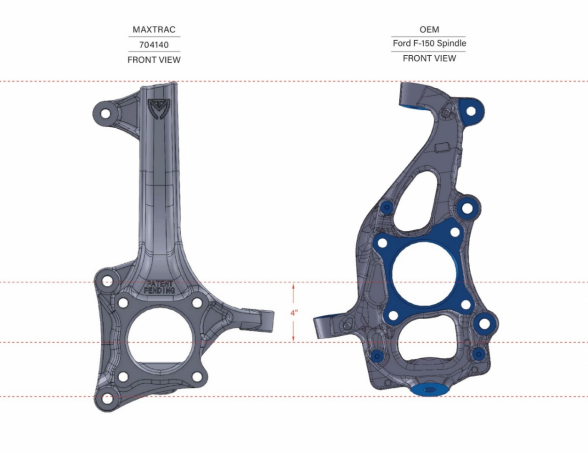

Another key component often used in 2WD kits is the lift spindle. A lift spindle maintains the original spacing between the ball joints but moves the hub mounting surface lower on the steering knuckle. This results in additional lift without changing control arm geometry or steering components. Because these systems keep all major components in their original locations, there’s no need to install a subframe, making 2WD lift kits simpler, more affordable, and easier to install.

Why 4WD Lift Kits Are Different

4WD (four-wheel drive) trucks have front differentials and axles, which change how suspension lift can be achieved. To create room for these drivetrain components while maintaining proper alignment and geometry, 4WD lift kits often include a subframe. This subframe lowers the suspension mounting points and allows clearance for the front axles, but also adds cost and complexity to the installation.

Why 2WD Lift Spindles Don’t Work on 4WD Trucks

One major difference between 2WD and 4WD trucks is the presence of front axles. On a 2WD lift spindle, the hub mounting surface is relocated downward, placing it in front of the lower ball joint. If you were to install this setup on a 4WD truck, the front axle would physically interfere with the lower control arm—making it mechanically incompatible.In addition, 2WD spindles are designed to maintain the original distance between upper and lower ball joints. This places the lower ball joint directly behind the wheel bearing, which prevents the use of a through-hole bore needed for a 4WD axle.

The Takeaway

For customers looking to lift a 2WD truck, these kits offer a more budget-friendly and straightforward solution compared to traditional 4WD lift kits. Since 2WD systems don’t require a subframe and involve fewer components, they’re easier to install and allow you to build your truck in stages—without having to discard or replace parts from earlier upgrades.

Whether you’re starting fresh or upgrading an existing setup, understanding these key differences will help you choose the right lift kit for your build. If you’re not sure what works best for your truck, our team is always here to help.